About Us

Refining For The Circular Economy

Refiniti Was Formed To Bring Together Leading Technologies In The Field Of Feedstock Recycling For Polymers. We aim to tackle the difficult materials unsuitable for traditional recycling methods and in doing so, complement rather than compete with mechanical recycling, to increase overall recycling rates of plastic waste.

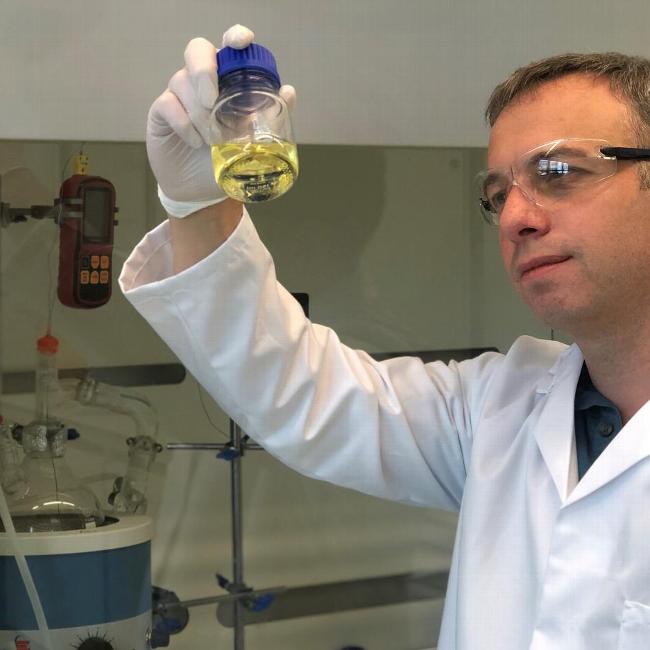

At Refiniti, we developed patented chemical separation technology and knowhow to enable a higher utilisation rate of pyrolysis oil. This technology removes the chemical elements that are responsible for catalyst poisoning, instability and equipment fouling.

In our process we utilise methods with a focus on minimising energy consumption. The majority of our refining process is carried out at ambient temperatures and pressures to minimise the carbon footprint and offer a more sustainable approach to chemical recycling.

We have worked with simple batch pyrolysis reactors through to more complex continuous systems as well as a range of reactor conditions and feedstock types. This provides flexibility with which to create a full line system that is targeted to produce outputs with characteristics desired by individual sectors of the petrochemical industry.

Quick Links

Visit Us

Refiniti LTD

Begbroke Science Park, Woodstock Road, Begbroke,

Oxfordshire,

OX5 1PF

Contact Us